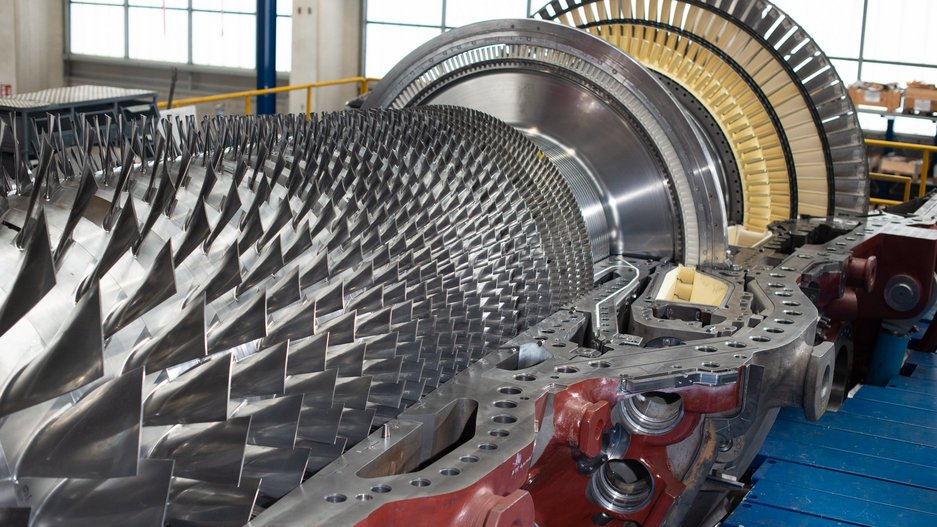

Award for the supply of one hydrogen-ready GT26 gas turbine and one steam turbine, along with their respective generators.

Electrolysers

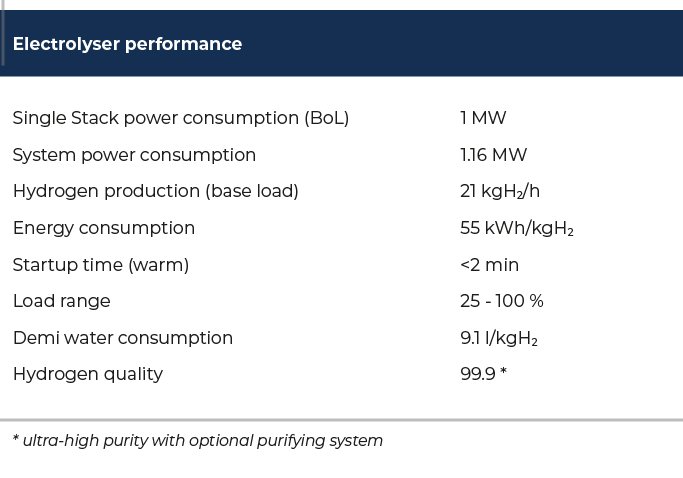

With a capacity of 1 MW of electrical input, the new Ansaldo Green Tech electrolyser is conceived for applications with large hydrogen production volumes. The Ansaldo Green Tech 1MW electrolyser is based on last generation Anion Exchange Membrane and innovative formulation for the anodic and cathodic catalysts, which enable efficient and high-purity hydrogen production, limiting gas crossover, even at large scales.

In addition to high hydrogen production rate, the electrolyser is also designed to optimize efficiency, flexibility, safety, and reliability.

High efficiency is ensured by an accurate selection of catalyst materials and deposition techniques, FEM based internal geometry optimization, electrolyte flow design based on CFD calculations and proper sizing of the auxiliary equipment to limit the plant energy consumption.

Safety and Reliability are ensured by an extensive monitoring of all the critical parameters that are proof of proper operating regime, which are, among others, process temperatures and pressures, output gas quality and crossover phenomena. The electrical supply is managed with all appropriate safety systems for the quickest and safest emergency actions. The unit features advanced methods to limit membrane deformation and stress, decreasing its degradation rate.

The control system allows fast and efficient transients, with full monitoring of all relevant process parameters.

The electrolyser can be installed on a green or brownfield area. It is designed for remote and unmanned operations. The control system, in charge of acquisition, monitoring, and regulation of hydrogen production as well as plant operation, is designed to support the electrolyser flexibility to operate with a variable power input from the grid. In particular, the system is suitable to operate associated to renewable energy sources such as photovoltaic or wind energy.

The standard installation is modular, based on an outdoor containerized solution, but in case of multi-megawatt plant, dedicated open design solutions are envisaged. The footprint required for 1 MW installation is less than 150 sqm.

Maintenance is minimal and dedicated service packages can be provided based on Customer needs, leveraging on remote monitoring and control of the main operational data.

In evidence

NUCLEAR ENERGY, FIRST GATE REVIEW OF THE EAGLES CONSORTIUM: ADVANCING DESIGN AND SAFETY FOR EAGLES-300

Ansaldo Nucleare, ENEA, RATEN and SCK CEN met in Mol, Belgium, from December 15 to 17 for the first Consortium gate review