EDM (Electrical Discharge Machining) is a specialized machining process characterized as unconventional because material removal occurs without direct contact between the tool and the workpiece. Instead, it relies on a series of high-frequency, controlled electrical discharges between an electrode (the tool) and the workpiece. These discharges generate localized micro-fusions that gradually erode the material.

The electrode and workpiece remain separated by a gap filled with a dielectric fluid, which varies depending on the specific EDM process used. This fluid is critical for insulating the gap and facilitating the discharge.

Type of EDM Processes

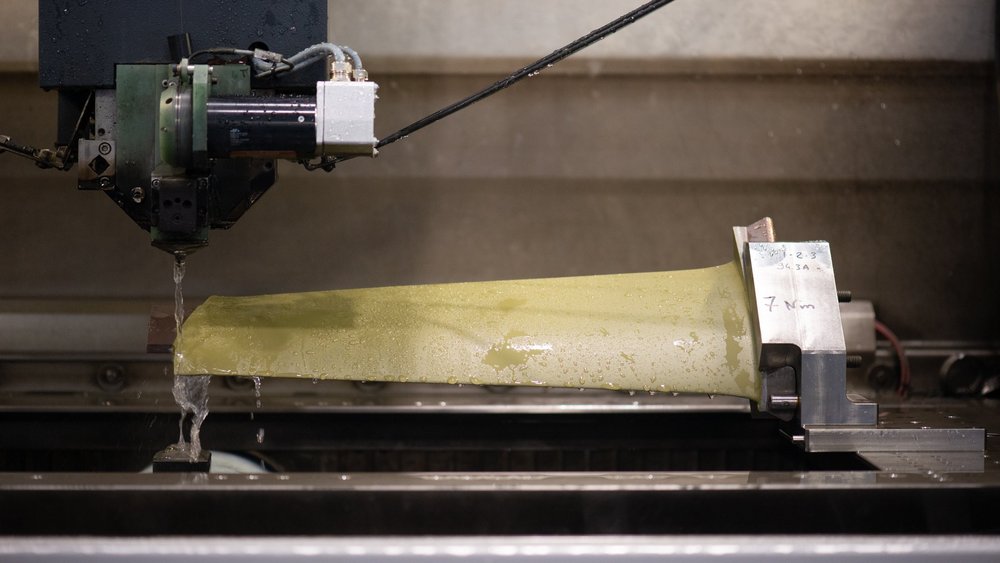

Plunge EDM:

This method uses a three-dimensional electrode, typically made of copper or graphite, to shape the workpiece in a negative form. By coordinating movements along the main axes (x, y, c, z), it produces intricate shapes, recesses, and cavities that are unattainable with conventional machining techniques.

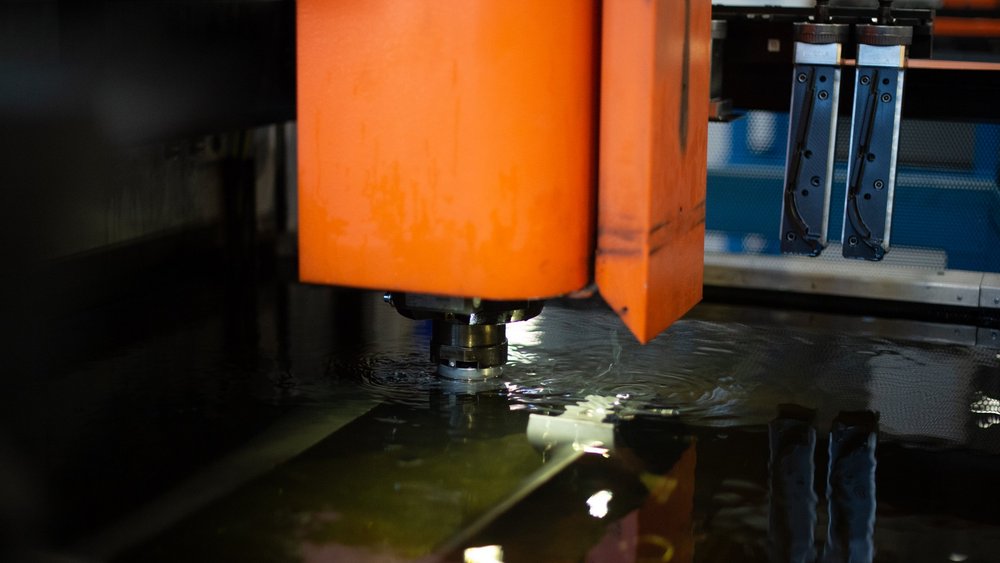

Wire EDM:

In this technique, the electrode is a thin wire, usually made of brass, which is tensioned vertically between two guides. The wire moves through the workpiece, enabling the cutting of highly precise and complex profiles.