The event highlighted the central role of innovation for the Group

Emission footprint reduction

Ansaldo Energia’s upgrade packages reduce NOx/CO and CO2 emissions, allowing Power Plants to comply with increasingly stringent regulations and adapt to new operating schemes.

Solutions include burners replacement, control software upgrade and the implementation of specific tools such as the AutoTune digital system, offered for all B/E/F-class gas turbines. AutoTune automatically adjusts the turbine parameters to maintain emissions and combustion dynamics within defined limits under varying operating and ambient conditions.

The CO2 emissions of Ansaldo Energia turbines when fueled with standard natural gas are 70% lower than coal, and in themselves represent a first step towards de-carbonization. Their low-carbon footprint is combined with outstanding flexibility: they can be adapted to burn different types of fuels. Leveraging on proprietary technologies, Ansaldo Energia Service can extend this flexibility to biofuels and advanced low- or no-carbon fuels while maintaining backwards compatibility with pure natural gas.

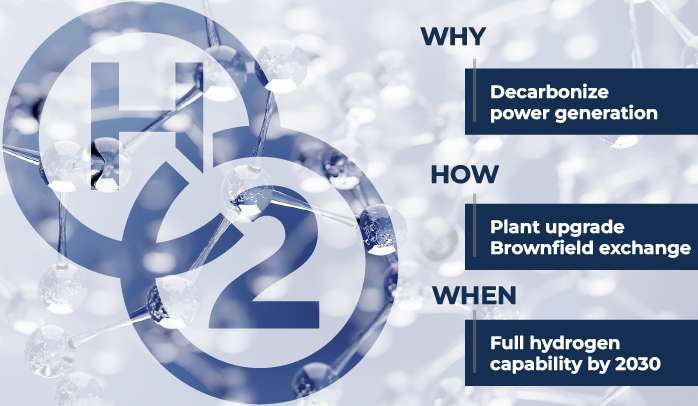

Fully-tested Ansaldo Energia solutions already are enabled to burn 50% hydrogen and more, targeting 100% by 2030 through an economically-feasible three-step roadmap:

- efficiency increase would allow owners access to national Energy Efficiency funding and to the “Efficiency Certificates” market;

- hybridization would lead to savings in ETS allowances and carbon tax;

- full decarbonization would allow further savings on ETS allowances and carbon taxes.

In evidence

ANSALDO ENERGIA TO UPGRADE ENERWAVE-OWNED THISVI POWER PLANT IN GREECE

The upgrade will increase the plant’s output while increasing overall efficiency