The event highlighted the central role of innovation for the Group

Power plants

Once the plant is in operation, Ansaldo Energia can ensure all maintenance and repair activities (supported by remote diagnostics tools) through Long Term Service Agreements or as service activities on demand.

Existing plants can also be upgraded to improve sustainability and efficiency, or even fully revamped with the substitution of the power island and the renovation of all Balance of Plant auxiliary systems.

The approach of Ansaldo Energia is founded on flexibility, agility, partnership.

Flexibility is at the heart of the Ansaldo Energia’s proposal. Pre-engineered modules are integrated into fully specific solutions tailored on Customer needs (variable load profile requirements, pure power generation or cogeneration, optimized plant start-ups), grid requirements, local opportunities and constraints.

Time-to-market flexibility is also offered with fast-track solutions for quick turn-key delivering.

In order to promote plant acceptance, all facilities are designed to respect the local socio-cultural framework and minimize the environmental impact.

The Ansaldo Energia offering encompasses Simple Cycle power plants as well as Gas&Steam Combined Cycles, Energy-Transition Combined Cycles, Geothermal and Nuclear power plants.

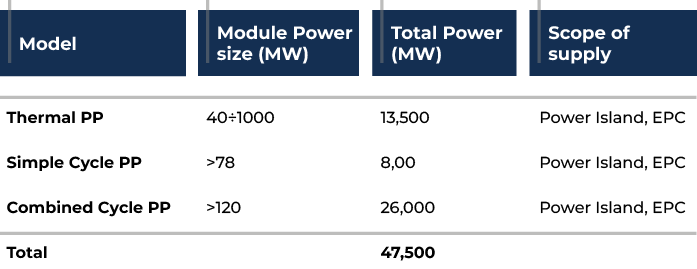

This rich portfolio is based on proven global experience: the total power of the machines built and commissioned by Ansaldo Energia since 1945 amounts to over 47 GW.

Once the plant is in operation, Ansaldo Energia can ensure all maintenance and repair activities (supported by remote diagnostics tools) through Long Term Service Agreements or as separate Services.

Existing plants can also be upgraded to improve sustainability and efficiency, or even fully revamped with the substitution of the power island and the renovation of all Balance of Plant auxiliary systems.

The approach of Ansaldo Energia is founded on flexibility, agility, partnership.

Flexibility is at the heart of the Ansaldo Energia’s proposal. Pre-engineered modules are integrated into fully specific solutions tailored on Customer needs (load profile requirements, peak or base load demand, pure power generation or cogeneration), grid requirements, local opportunities and constraints.

Time-to-market flexibility is also offered with fast-track solutions for quick turn-key delivering.

In order to promote plant acceptance, all facilities are designed to respect the local socio-cultural framework and minimize the environmental impact.

The Ansaldo Energia offering encompasses Simple Cycle power plants as well as Gas&Steam Combined Cycles, Energy-Transition Combined Cycles, Geothermal and Nuclear power plants.

This rich portfolio is based on proven global experience: the total power of the machines built and commissioned by Ansaldo Energia since 1945 amounts to over 250 GW.

Simple cycle gas turbine plants play a decisive role in supporting the stability of the electricity grid, as they can be started up quickly to respond to rapid variations in demand...

A Combined cycle power system uses a gas turbine to drive an electrical generator, as Simple cycle plants; in addition, it recovers the heat of the turbine...

BRINDISI POWER PLANT

The Combined Cycle EniPower plant in Brindisi, powered by Ansaldo Energia, has been burning a blend of natural gas and hydrogen since 2006. This represents one of the most extensive experiences worldwide of hydrogen use in power generation.

The Brindisi thermoelectric plant adopts F-class AE94.3A turbines featuring advanced self-adjustment capability: they can run on 100% natural gas, or mix it with hydrogen at varying concentrations up to 25%.

Fluctuations in hydrogen rate are due to the use of off-gas coming from a nearby chemical plant, and do not affect NOx emissions – which are always kept within the established regulatory limits.

The two AE94.3A units involved in the experience have cumulated a total of >250,000 Equivalent Operating Hours, allowing 45,000 tons / year of CO2 savings. This corresponds to the average CO2 emissions of about 20,000 passenger cars.

MOST SIGNIFICANT GLOBAL PROJECTS

-

800 MW

- Yeni Elektrik Üretim Gebze, Turkey

- Sorgenia Turano Lodigiano, Italy

- Scope of work: EPC Contractor

-

1,200 MW

- EniPower Brindisi, Italy

- Scope of work: supply of whole Power Block

-

1,500 MW

- East Delta Electricity Al Shabab, Egypt

- Scope of work: transformation of a Single Cycle power plant into a Combined Cycle power plant

-

1,550 MW

- OPWP Ibri, Oman

- Scope of work: supply of Gas Turbines

-

1,750 MW

- OPWP Sohar III, Oman

- Scope of work: supply of Gas Turbines

-

2,250 MW

- EEHC Giza North, Egypt

- Scope of work: supply of Steam Turbines and Generators

In evidence

ANSALDO ENERGIA TO UPGRADE ENERWAVE-OWNED THISVI POWER PLANT IN GREECE

The upgrade will increase the plant’s output while increasing overall efficiency