An important recognition for the research project coordinated by Ansaldo Energia

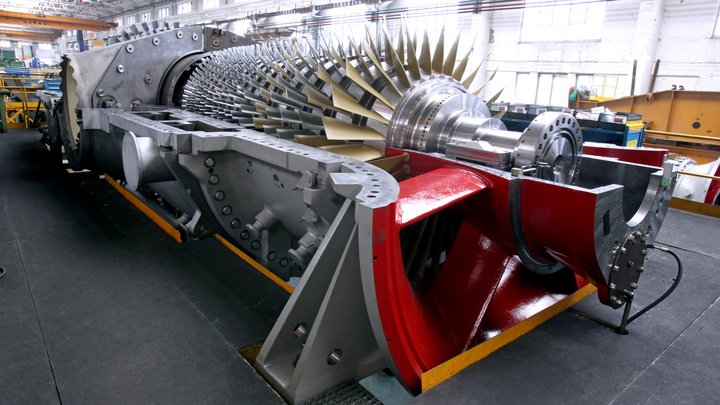

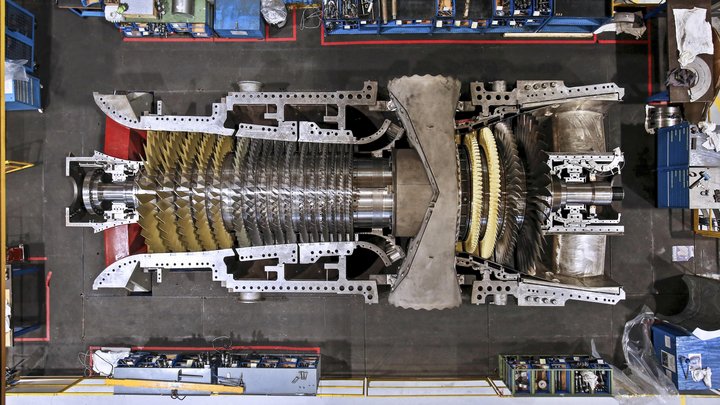

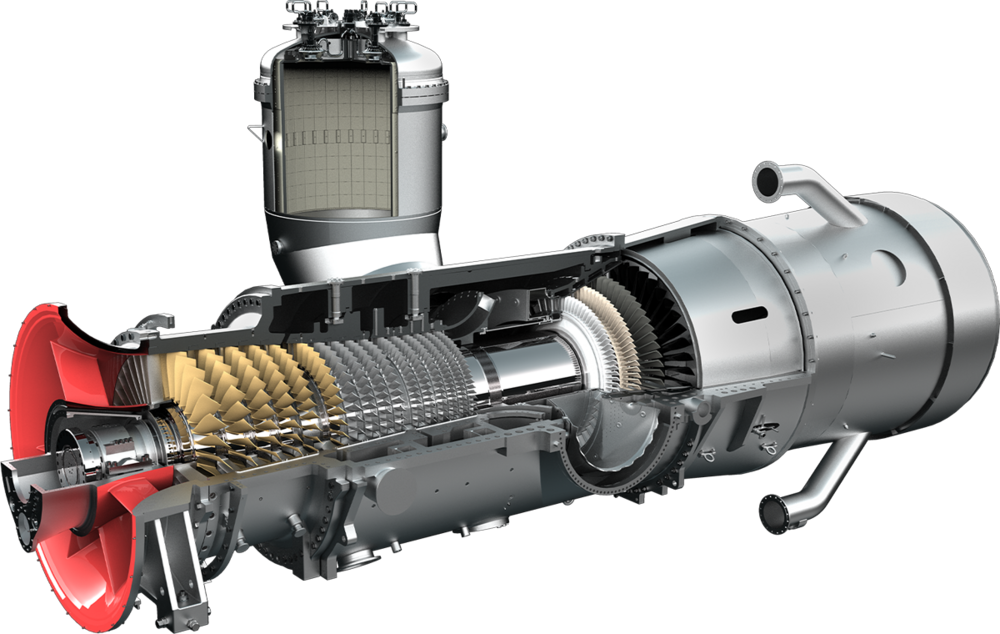

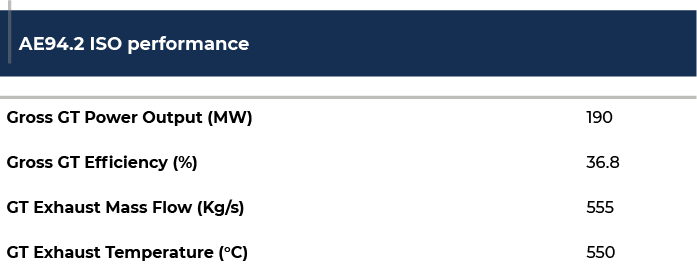

AE94.2 - The robust value

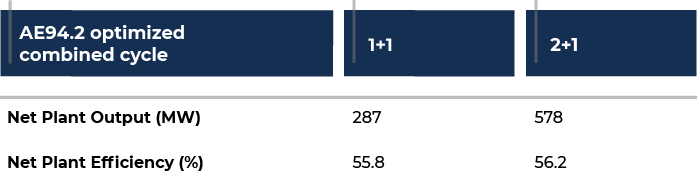

Robust overall design, rotor stiffness and excellent combustion stability (due to two external combustion chambers), make the Ansaldo Energia AE94.2 the right choice when fuel diversification and/or fast transient phases are required.

AE94.2 turbines offer fast start capability, extreme operation simplicity and superior fuel flexibility (2 minutes gas-to-oil and oil-to-gas fuel switchover).

They can be profitably used in simple or Combined Cycle, for base or peak load, when grid conditions are severe and in areas where power generation is based on alternative fuels.

The special AE94.2K version is specifically designed for burning low- and very low-BTU gases from steel mill or refinery processes.

The AE94.2s fleet is characterized by more than 25 years of successful operation and over 10 million EOH, with an excellent record of robustness, operational flexibility and durability.

In evidence

BIRR TEST FACILITY TO PROVIDE STRATEGIC RESERVE POWER FOR SWITZERLAND’S ENERGY SECURITY

This enhancement marks a new chapter for the Ansaldo Energia’s site