Ansaldo Nucleare, ENEA, RATEN and SCK CEN met in Mol, Belgium, from December 15 to 17 for the first Consortium gate review

Reheat - Efficent and flexibile

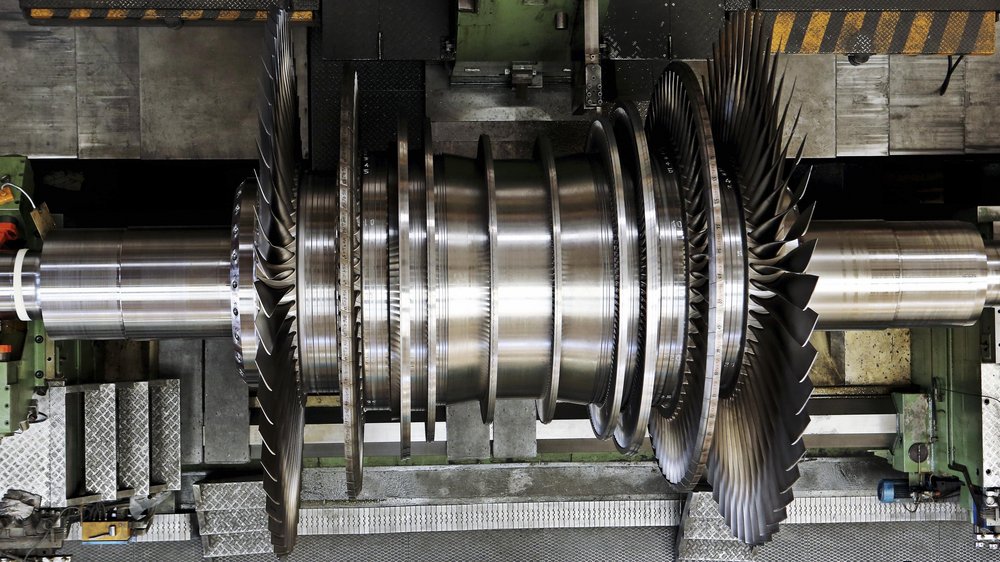

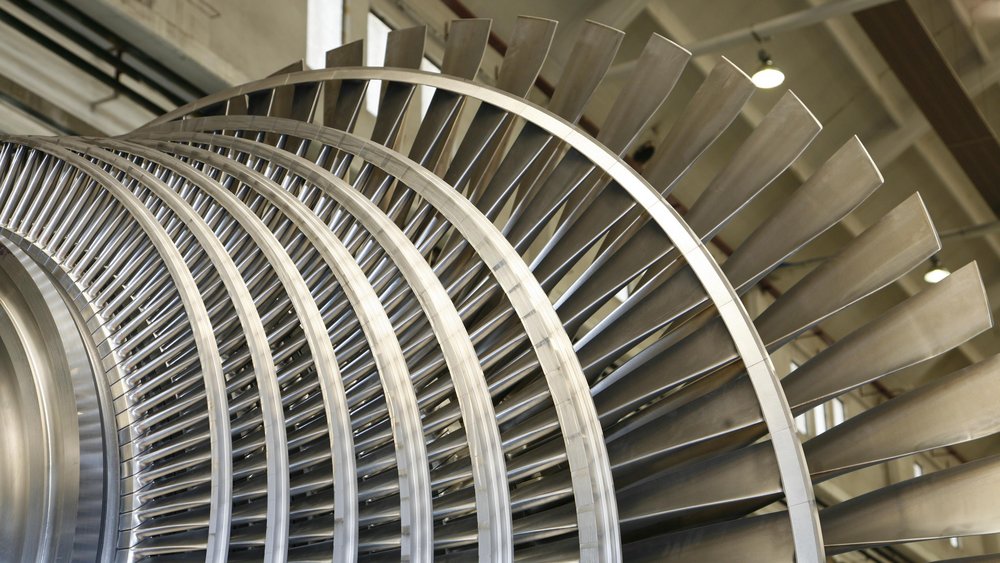

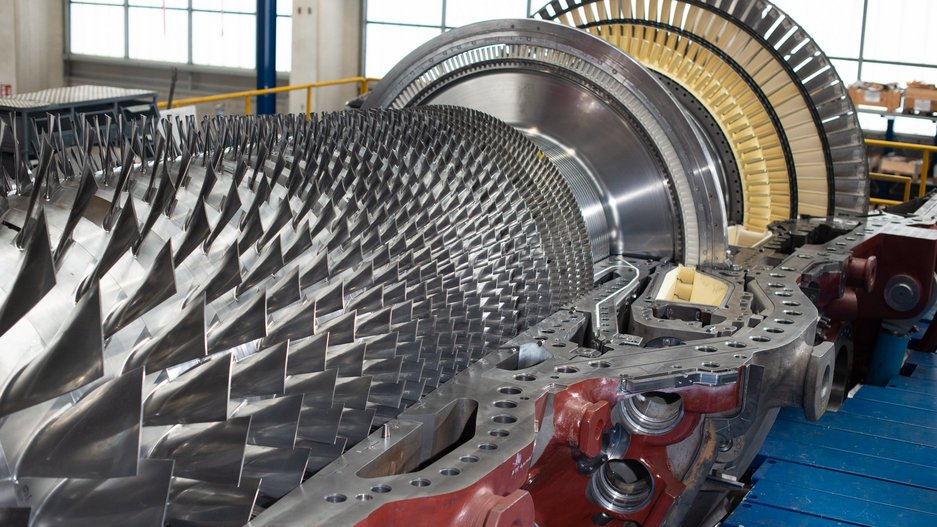

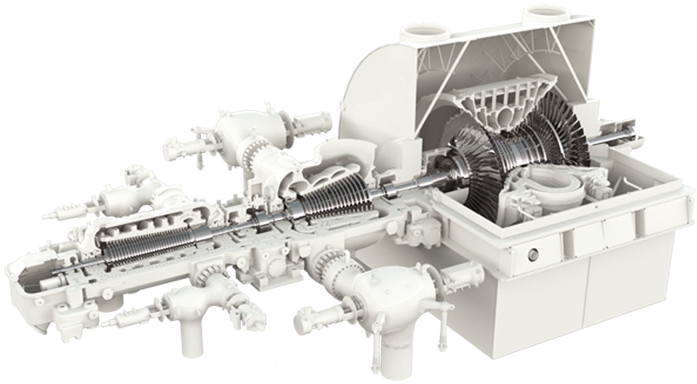

Reheat steam turbines increase efficiency by returning partially-expanded steam to the steam generator for reheating before feeding it back to the turbine.

The Ansaldo Energia reheat steam turbines portfolio includes machines from two to five cylinders, capable of covering a wide range of steam cycles, site conditions and operating modes.

For small ratings, the design concept is based on two cylinders with single-flow exhaust.

For higher ratings, the design is based on separate high-pressure and intermediate-pressure sections with one (or more) double-flow low-pressure sections. This configuration is suitable for Combined Cycles with advanced F- and H- class gas turbines as well as fossil power plants with the highest steam parameters for supercritical/ultrasupercritical conditions.

In evidence

FLEX4H2 RECEIVES THE BEST SUCCESS STORY AWARD: ADVANCING FUEL FLEXIBILITY FOR THE ENERGY TRANSITION

An important recognition for the research project coordinated by Ansaldo Energia