The agreement has been signed with TSK UK

GT36 - The superior value

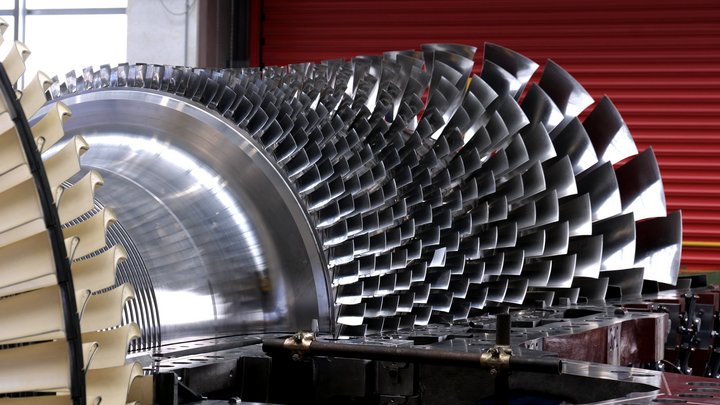

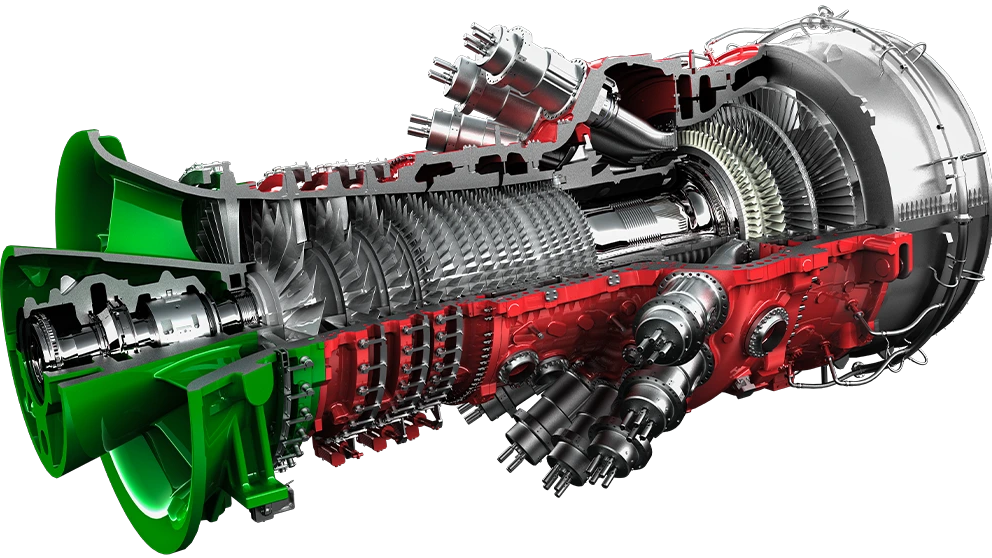

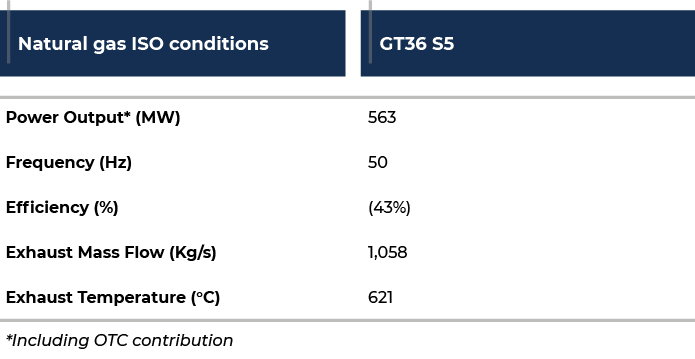

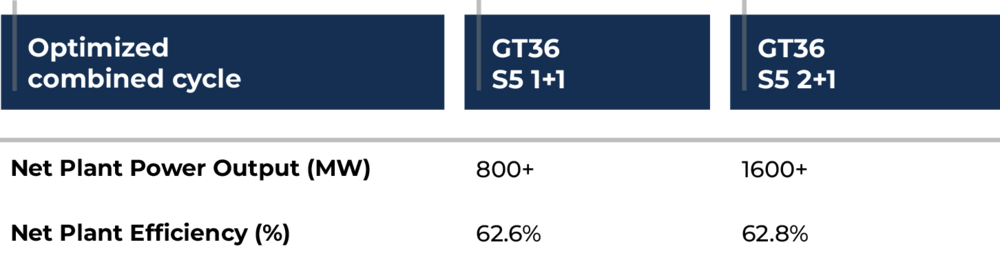

Ansaldo Energia’s H-class GT36 turbines leverage on the GT26 experience to ensure maximum dispatching and reduce electricity costs while minimizing CO2 emissions.

The unique sequential combustion solution that the GT36 adopts extends the emission-compliant operating window compared to other technologies.

The GT36 engine represents a future-proof investment, for its high efficiency, and its best-in-class 70% hydrogen capability, also enabled by sequential combustion.

Based on two successive combustion stages, it recovers the derating of the first stage by shifting the fuel into the second stage. This allows for full operational flexibility with low NOx emissions.

In evidence

INNOVATION DAY: NEW PATENTS AND PROCESSES, ANSALDO ENERGIA CELEBRATES INNOVATION WITHIN THE GROUP

The event highlighted the central role of innovation for the Group